Geologic Exploration & Anomaly Detection

Horizontal directional drilling provides the mining and tunneling industries with an effective and practical geologic exploration tool. Coupling LWD/MWD with Geosensing, REI Drilling, Inc. has established the approach for characterization of geologic structure, discontinuities, intrusions, the integrity of geologic strata, the proximity of gas or water producing sources, significantly in advance of mining. Directional drilling coupled with Geosensing can confidently derive the relative hardness of the roof, floor, interspersed rock partings, channeling, and igneous intrusions, and the proximity of - and magnitude of - water or gas inflows, which provides the ability to characterize the following in advance of coal mining: (i) the lateral extent and thickness of sandstone channels, (ii) the orientation and displacement of faults, (iii) changes in geologic structure, such as folding and rolls, (iv) the presence and extent of interbedded partings, (v) changes in the overlying and underlying strata, including composition, (vi) the extent and the hardness of igneous or clay intrusions (to determine cutting path for example), (vii) the lateral extent of coal burn, and (viii) the location of fractures and faults including their relative contribution to water or gas inflows. Directional drilling coupled with Geosensing is particularly effective for geologic characterization of bedded evaporite deposits in advance of mining, as interbedded strata which could not be detected without Geosensing are identified, including water soluble, and very weak zones of strata, including anomalous zones related to water inflows.

Fault and Anomaly Characterization

Download Case Studies

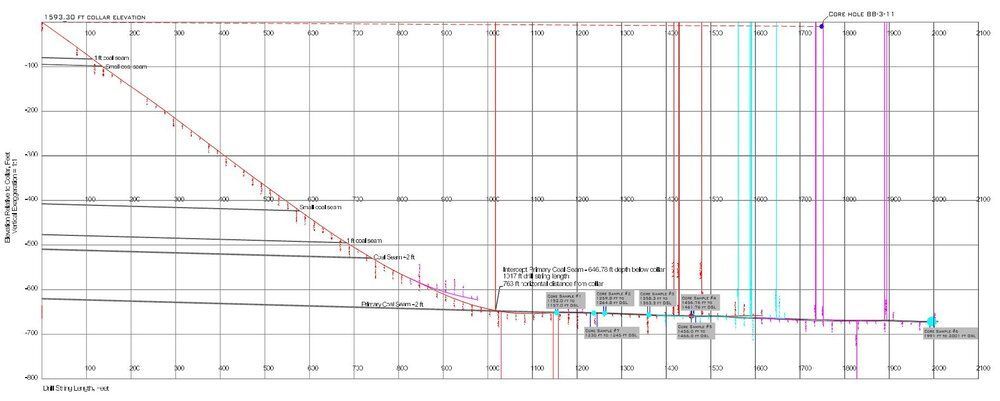

Download Case StudiesDirectional holes provide a wealth of information about bedded deposits. REI uses directional drilling and sidetracking to maintain boreholes in the seam over distances up to 6,000 feet, and by plotting the profile of the borehole from downhole surveys and driller logs, REI provides the mining operation with an indication of seam structure along the full length of the borehole. Sidetracks are developed and intentionally drilled into the roof and floor rock at corresponding drill string lengths to compare elevation data to estimate the seam thickness.

Structure Characterization

Download Case StudiesVertical boreholes, such as historic gas wells in advance of mining developments, are often unable to be accessed from the surface. In these cases, horizontal drilling can be employed to verify the locations. REI can develop parallel horizontal boreholes on either side of a magnetic anomaly, and use a magnetic gradiometer to verify the vertical hole location with a high level of accuracy. This novel approach allows mines to locate objects such as vertical well casings, giving the confidence to continue development.

Geophysical Surveys and Geotechnical Drilling

Download Case StudiesREI uses directional drilling to gather geophysical data from hard-to-reach areas of mining operations that would not be possible with traditional non-directional techniques. REI can steer a borehole along a determined alignment and run a post-drilling geophysical survey, including continuous gamma, televiewers, and a range of other tooling. Additionally, REI can collect core samples and perform overcore stress tests to provide geotechnical data, as well as stress data points

Coal Quality Characterization

Download Case Studies

Download Case StudiesThrough sidetracking, directional drilling maximizes the amount of data gathered from each corehole while minimizing total footage drilled. Increased borehole design capabilities allow for optimal borehole placement and core retrieval. REI has experience from surface and underground setup locations, so call us for more information to see if directional techniques can improve your exploration program.